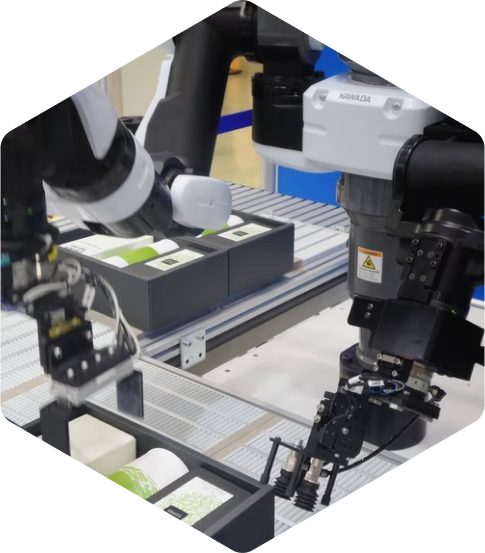

Performing For You

Outfitting the first machine is simply the beginning. OMNI is invested in making our customers successful and yours. Our proven track record working with the largest OEMs in the packaging industry speaks for itself. However, our continued success working cooperatively together project after project, product line after product line speaks much louder.

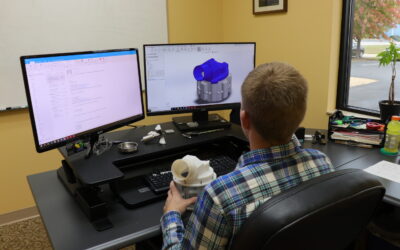

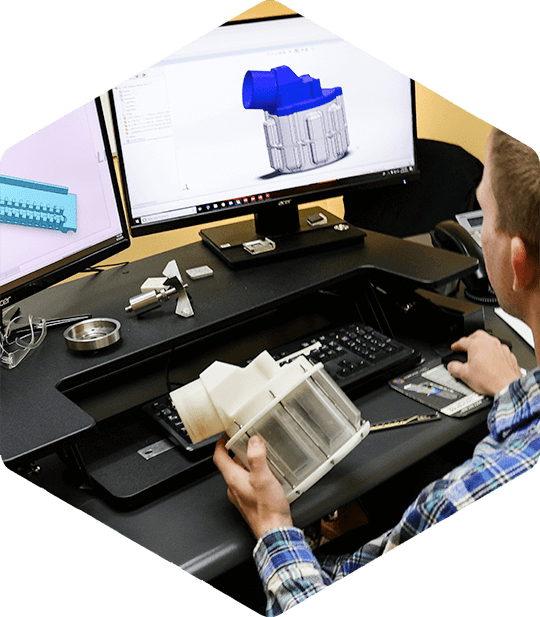

Our Process

When every customer starts working with OMNI, many questions need to be answered. It is important to us that each interaction is handled consistently, professionally, and with one goal in mind. Creating value for our customers. Because of this, we want to ensure that you know just what to expect from start to finish when you work with OMNI. We call this the OMNI Process.

- Collaborative opportunity evaluation

- Designing your innovative solution

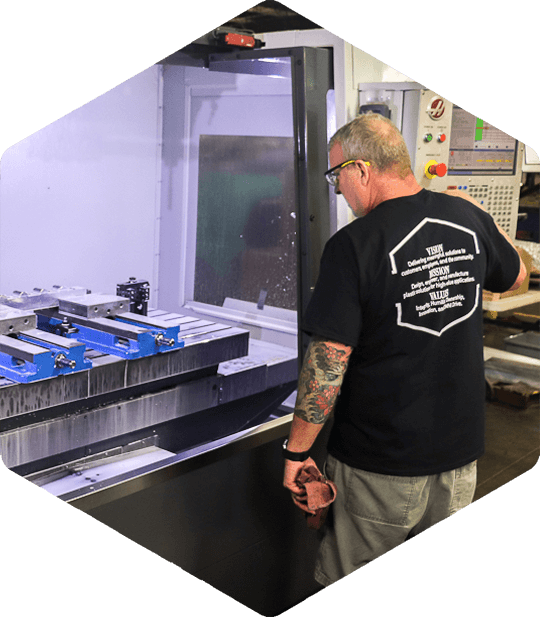

- Making your mold

- Manufacturing your solution

- Performing for you

Our Blog

Molded for Life: Understanding the Longevity and Aging of Plastic Parts

Plastics are everywhere, from household items to critical industrial components. To ensure their longevity and performance, it’s crucial to understand how plastic parts age. Basics…

Overcoming Common Challenges in Molded Plastic Part Production

Molded plastic parts play a crucial role in various industries, from OEMs to packaging machinery to industrial automation. While the production of these parts offers…

Choosing the Right Plastic Material for Your Molded Parts

Creating your custom plastic parts can be the beginning of a new era for your organization. With custom parts specifically created for OEMs, your organization…

Project Form

Too soon to fill out a project request?

Learn more about our OMNI PROCESS and see other part projects by clicking here.

Most Frequently Asked Questions

What tolerances can you hold in your plastic parts?

OMNI holds to standard dimensional practices. The majority of the parts that we manufacture are at a two place decimal level and held to ±.01". However, there are instances where that is not good enough, or that may be overkill. Depending on the specifics OMNI can hold ±.005" on specific features by molding the part to size, or machining a specific dimension to accomplish the overall requirement.

After you create my mold, what should I expect my lead-time to be on repeat orders?

At OMNI we desire to be responsive to our customers' needs. Lead-times fall into a few categories, standard runs and long runs. The quantity of parts required dictates the expected lead-times. Normal repeat orders would fall into a 3-5 week window.

Your product will need to be cleaned and sanitized, how would we go about doing that?

Each elastomer is different, however the majority of the products that we handle are able to have CIP (Clean In Place) requirements put on them. The fact that these materials are fairly corrosion resistant, combined with a hygienic design, allow for extremely sanitary components. Many of the materials we utilize have operating temperatures of 185°F and can stand up to hot water, not steam, and most standard cleaning agents provided that are at the proper dilution rate.

How does plastic hold up to wear and tear compared to SS or another metal?

This is a great question and one we love to answer. Yes, yes it can! Many polymers, specifically polyurethanes, have outstanding abrasion resistance and toughness due to the wide range of durometers available. These materials can be extremely soft and compliant to extremely rigid like a bowling ball. This affords us the flexibility to optimize the design and functionality. There is a reason why salt truck blades and salter chutes are made from polymers and not metals. Impingement resistance and corrosion resistance.