Here is an example of how OMNI can help take an expensive fabricated part and not only improve the cost but actually improve the part AND its performance.

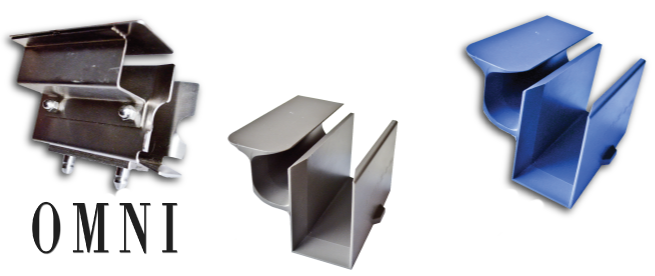

In the photos below you will note a fabricated stainless steel assembly on the far left. This is a bucket/tray that holds a carton that gets loaded with a foil-wrapped brick of cream cheese. The feature on the upper left holds the major flap of the carton and the large pocket holds the erected box. As you can imagine, the fabricated part is very expensive, very heavy, has fasteners that can come loose around the product and is a haven for bacteria. In a jam the stainless part gets bent becoming obsolete.

With some design input from OMNI, we helped to create a one-piece, food grade, easy to sanitize part with NO seams or welds in a material that is impact resistant. Showing on the far right is the 3D printed prototype that was used for fit testing and the part in the center is the final production part.

If you have any applications that the OMNI Team might be able to help with, please email info@omnitechnologies.com or start our project here.